Seat Valves

Seat Valves

Seat valves are the extremely reliable all-rounders in the valve technology segment. This robust valve design with pneumatic or motorised actuators offers a high number of maintenance free cycles in difficult on/off and control applications such as steam, gaseous media and contaminated liquids. They also do not cause any water hammers when installed to close against the media flow. The Schubert & Salzer seat valves are made of stainless steel or red brass. All are designed with a variety of end connections and are suitable for a wide temperature range.

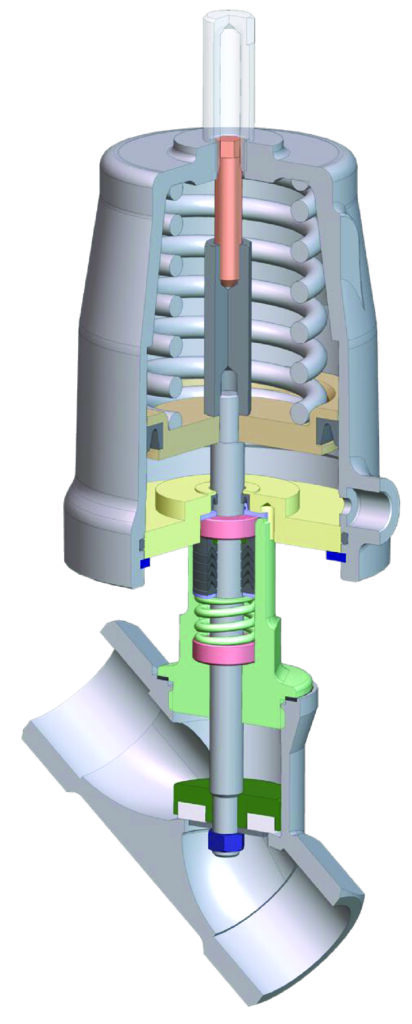

Design principle of seat valves

The shut-off device in Schubert & Salzer seat valves comprises a plug with a seal that seals against the seat. The use of a control plug enables the flow to be reduced depending on the valve opening. The pneumatic or linear actuators that are used are connected to the valve plug by means of a piston rod and they work independently from the operating medium. The dynamic sealing of the piston rod is realised by a self-adjusting packing. Seat valves can be flowed through from both directions, whereat in case of liquids, the preference is to close against the plug, in order to avoid water hammers and pressure peaks.

The advantages of seat valves

- Robust and compact valve allrounder

- High switching performance and wear resistance

- Reliable shut-off function

- No water hammers when closing against the media flow

- High degree of tightness, low leakage

- Wide operating temperature range

- Simple insulation, low heat losses

- High KVS value

- Easy to install and maintain